Choose the 316/316L Stainless Steel for you

316/316L stainless steel is a molybdenum-containing austenitic stainless steel that is far more resistant to corrosion than 304 stainless steel, especially pitting and crevice corrosion in chlorides (such as salt water and de-icing salts). This makes it an ideal choice for demanding applications such as marine environments, chemical processing, medical devices, and food processing. As a professional stainless steel supplier, we offer a full range of 316/316L stainless steel products that meet international standards such as ASTM and EN, ensuring the highest quality materials for your project.

316/316L Stainless Steel Available Forms:

We have a complete stock of 316/316L stainless steel in various shapes and sizes, and can customize it according to your drawings.

Sheet & Plate: 0.3mm – 100mm, surface treatment (2B, BA, No.1, No.4, HL, mirror).

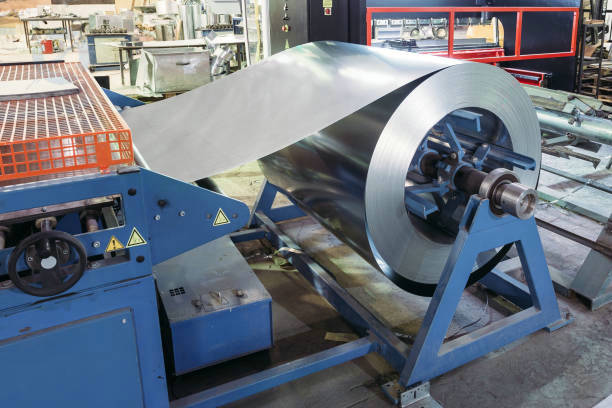

Coil/Strip: Width up to 2000mm

Pipe & Tube: Seamless / Welded

Bar/Rod: Round / Flat / Hex / Square, etc.

Wire Rod / Wire Mesh

Custom Processing Services: laser cutting, plasma cutting, bending, welding.

Why Choose HuaRun Metals as Your 316/316L Stainless Steel Supplier?

10,000+ Tons Inventory

Ready-to-ship 316/316L stainless steel in coils, sheets, plates, and bars for fast global delivery.

24-Hour Dispatch

Efficient warehousing and logistics ensure your order is dispatched within 1 business days.

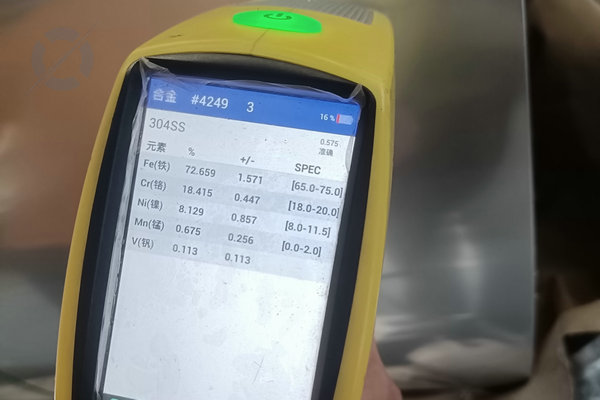

ISO & MTC Certified

Full Mill Test Certificates (EN10204 3.1) and ISO 9001 compliance for every shipment.

Exported to 50+ Countries

Trusted by global clients in the UK, EU, Southeast Asia, Middle East, and South America.

316/316L Stainless Steel Data Sheet

316 and 316L stainless steel are nearly identical in performance, with the only key difference being the carbon content.

- 316 stainless steel: The upper carbon content is 0.08%.

- 316L stainless steel: The “L” stands for “Low Carbon” and its upper carbon content is 0.03%.

What does this mean for you?

316L is the more versatile choice. Its lower carbon content minimizes carbide precipitation during welding, which prevents intergranular corrosion in the weld. Therefore, 316L is highly recommended for applications that require a lot of welding. In most cases, 316/316L is Dual Certified, meeting the standards of both 316 and 316L, giving you maximum flexibility.

Chemical Composition of 316/316L Stainless Steel (ASTM A240)

| Element | 316 (%) | 316L (%) |

|---|---|---|

| C | ≤ 0.08 | ≤ 0.03 |

| Mn | ≤ 2.00 | ≤ 2.00 |

| P | ≤ 0.045 | ≤ 0.045 |

| S | ≤ 0.030 | ≤ 0.030 |

| Si | ≤ 0.75 | ≤ 0.75 |

| Cr | 16.0 – 18.0 | 16.0 – 18.0 |

| Ni | 10.0 – 14.0 | 10.0 – 14.0 |

| Mo | 2.00 – 3.00 | 2.00 – 3.00 |

Mechanical Properties of 316/316L Stainless Steel (ASTM A240)

| Property | 316 | 316L |

|---|---|---|

| Tensile Strength (MPa) | ≥ 515 | ≥ 485 |

| Yield Strength (MPa) | ≥ 205 | ≥ 170 |

| Elongation (%) | ≥ 40 | ≥ 40 |

| Hardness (Brinell, HBW) | ≤ 217 | ≤ 217 |

Physical Properties of 316/316L Stainless Steel

| Property | Value |

|---|---|

| Density | 8.00 g/cm³ (approx.) |

| Melting Point | 1375 – 1400°C |

| Thermal Expansion Coefficient | 16.0 µm/m·°C (0–100°C) |

| Thermal Conductivity | 16.3 W/m·K (at 100°C) |

| Electrical Resistivity | 0.074 ×10⁻⁶ Ω·m (at 20°C) |

| Specific Heat Capacity | 500 J/kg·K |

| Modulus of Elasticity | 193 GPa |

International Equivalent Grades for 316 / 316L Stainless Steel

| Standard / Country | 316 Equivalent Grade | 316L Equivalent Grade |

|---|---|---|

| UNS (USA) | S31600 | S31603 |

| ASTM / ASME (USA) | ASTM A240 / A276 Type 316 | ASTM A240 / A276 Type 316L |

| EN / DIN (Europe) | X5CrNiMo17-12-2 (1.4401) | X2CrNiMo17-12-2 (1.4404) |

| JIS (Japan) | SUS 316 | SUS 316L |

| BS (UK) | 316S31 | 316S11 |

| ISO | 316 | 316L |

| GB (China) | 0Cr17Ni12Mo2 | 00Cr17Ni14Mo2 |

| AFNOR (France) | Z7CND17-11-02 | Z2CND17-12 |

| GOST (Russia) | 03Ch17N14M3 | 03Ch17N13M2 |

Applications of 316/316L Stainless Steel

Marine Engineering

Used in the manufacture of marine hardware, propeller shafts, railings and heat exchangers to resist seawater corrosion.

Chemical and Petrochemical

Used in the manufacture of storage tanks, pipes, valves and reactors to handle a variety of corrosive chemicals.

Pharmaceutical and Medical

Used in the manufacture of surgical instruments, medical implants (such as bone screws) and sterile production equipment due to its biocompatibility and easy cleaning.

Food and Beverage Processing

Used in the manufacture of brewing tanks, milk coolers and processing equipment to ensure hygiene and prevent metal contamination.

Building and Structures

Used in building facades, railings and structural parts in coastal areas for both beauty and durability.

FAQ

Is 316 stainless steel magnetic?

As an austenitic stainless steel, 316 is non-magnetic in the annealed state. However, it may become slightly magnetic after cold working (such as bending or stretching).

Can 316L stainless steel be used for food contact?

Yes, both 316 and 316L stainless steel are considered food grade and are widely used in the food and beverage industry because they do not react with food and are easy to clean and sterilize.

What kind of material certificates can you provide?

We can provide a Material Test Certificate (MTC) in accordance with EN 10204 3.1 standard for each shipment, detailing the chemical composition and mechanical properties test results.

What is the minimum order quantity?

We do not have a strict minimum order quantity requirement for standard stock products, but please contact our sales team for specific circumstances and we will provide the best solution based on your needs.

316 vs 304 Stainless Steel – How to Choose?

| Feature | 316 / 316L Stainless Steel (Recommended) | 304 / 304L Stainless Steel |

|---|---|---|

| Main Alloy Elements | Chromium, Nickel, Molybdenum | Chromium, Nickel |

| Corrosion Resistance | Excellent, especially resistant to chlorides | Good, but susceptible to chloride attack |

| Typical Applications | Marine equipment, chemical containers, implants | Kitchenware, architectural trim, general use |

| Cost | Higher | Lower |

| Selection Advice | Choose 316/316L for environments with saltwater, chemicals, or high corrosion risk. | Ideal for indoor or non-corrosive environments as a cost-effective solution. |

Our experts are ready to help you select the right 316/316L stainless steel material. Contact us today for a free technical consultation and competitive quote!