Special Alloy

Looking for reliable alloy steel or nickel alloy suppliers? HuaRun Metals offers a full range of high-performance materials including Monel 400, Inconel 600/625, Hastelloy C22/C276, Alloy 20, and more.

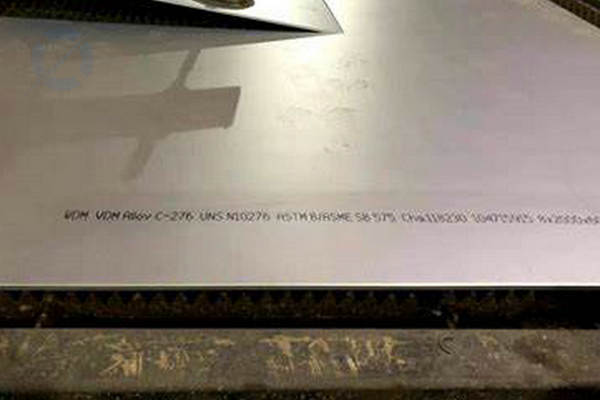

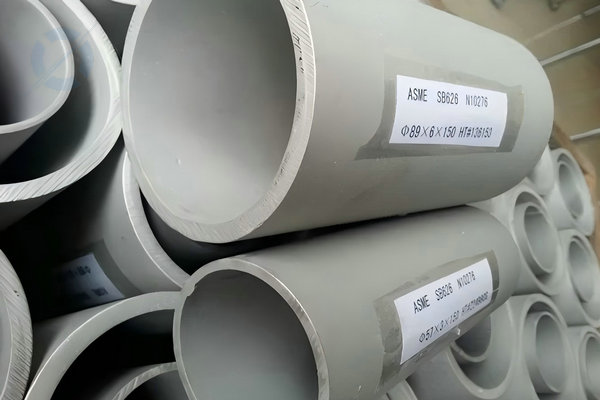

Available in forms such as plates, round bars, seamless tubes, and wires, our alloy products are ideal for use in extreme environments such as chemical plants, power generation, and marine industries. All materials come with certified documentation.

Contact us for alloy stock availability and pricing!

Special Alloy Grade

- Hastelloy Alloys: C-22 / C-276, etc.

Inconel Alloys: 600 / 601 / 625 / 718, etc.

Incoloy Alloys: 800H / 825, etc.

Monel Alloys: 400 / K-500, etc.

Titanium Alloys: Grade 2 / Ti-6Al-4V (Grade 5), etc.

As a leading specialty alloy supplier and specialty alloy manufacturer, we provide tailor-made, high-performance materials for a variety of demanding applications. Whether you are looking for specialty alloy sales, specialty alloy prices, or custom alloy solutions, our company is committed to exceeding your expectations.

Special Alloy Forms

- Sheets/Plates: No.1, 2B, 2D, Perforated, Checker, Embossed, Etch, Mirror, BA, No.4, etc.

- Coils/Strips:

- Bars: Round, Square, Flat, Hexagon, rectangular, etc.

- Tube: Round, Square, Flat, Hexagon, rectangular, etc.

- Seamless Tube: Mechanical & Hydraulic, etc.

- Wires: Wire Rod, Wire Mesh, etc.

Special Alloy Shapes

We provide special alloy plates, coils, strips, bars, tubes, wires, etc. in different grades and specifications.

Ready to source premium special alloys at competitive prices?

Contact us now to:

Get the latest Special Alloy Prices

Learn more about our Special Alloy Stock

Discuss customized alloy solutions

Arrange prompt shipment for your project

Special Alloy Applications

Special alloys from HuaRun Metals are indispensable in numerous high-demand sectors:

- Aerospace: Turbine engines, structural components, heat shields

- Oil & Gas: Downhole equipment, risers, pipelines

- Power Generation: Nuclear reactors, gas turbines

- Marine: Subsea equipment, shipbuilding components

- Chemical Processing: Reactors, pressure vessels, pumps

- Medical: Surgical instruments, implants

- Automotive: Racing components, exhaust systems

- Electronics: Sensors, connectors, precision instruments

Looking for a trusted Special Alloy Supplier? Contact HuaRun Metals for your project solutions!

How to Choose the Right Special Alloy?

Selecting the appropriate special alloy is critical to ensuring the success and longevity of your project. At HuaRun Metals, we recommend considering the following key factors when choosing a special alloy:

Identify Your Application Requirements

Evaluate the service conditions where the alloy will be used:

Corrosive Exposure:

- Application: Chemical plants, offshore platforms, desalination systems

- Recommended Alloys:

- Hastelloy C-276 for extreme chemical resistance

- Alloy 20 for sulfuric acid resistance

- Duplex Stainless Steel 2205/2507 for excellent chloride resistance at a lower cost

High Temperatures:

- Application: Aerospace engines, industrial furnaces, gas turbines

- Recommended Alloys:

- Inconel 625/718 for outstanding strength at elevated temperatures

- Waspaloy for superior creep resistance in aerospace components

Mechanical Stress:

- Application: High-pressure reactors, deep-sea drilling equipment

- Recommended Alloys:

- Monel K-500 for high strength combined with corrosion resistance

- Titanium Grade 5 (Ti-6Al-4V) for exceptional strength-to-weight ratio

Mechanical and Physical Properties

When your project demands specific mechanical performance, select based on:

High Strength:

- Recommended Alloys: Inconel 718, Monel K-500

Fatigue and Creep Resistance:

- Recommended Alloys: Waspaloy, Rene 41

Thermal Stability:

- Recommended Alloys: Incoloy 800H for high-temperature structural applications

Low Thermal Expansion:

- Recommended Alloys: Invar 36 for precision instruments

- Selecting alloys with the right mechanical profile ensures optimal performance and extends component life.

Cost-Effectiveness

Balancing material selection with project budget:

For cost-conscious corrosion-resistant projects,

- 2205 duplex stainless steel is more cost-effective than high-end nickel alloys.

For moderately high temperature needs,

- Incoloy 800H is a more economical alternative to high-temperature alloys such as Inconel 718.

Need a custom alloy recommendation based on your budget? Contact us to help you select the right alloy material with cost-effectiveness.

Industry Standards and Certifications

Make sure the alloy you choose meets the necessary specifications:

- Aerospace applications: choose materials certified by AMS or ASTM, such as Inconel 718 or Waspaloy.

- Chemical processing industries: prefer alloys certified for corrosive applications, such as Hastelloy C-22.

- Medical devices: use grade 2 or grade 5 titanium alloys that meet ISO 13485 standards.

All specialty alloys supplied by our company strictly meet international quality standards to ensure reliability and traceability.

Fabrication and Processing Requirements

Choose an alloy based on your fabrication capabilities:

Easier to Machine:

- Recommended alloys: Monel 400, Titanium Grade 2

Good Weldability:

- Recommended alloys: Inconel 625, Duplex 2205

Special Fabrication Needs:

- Alloys like Hastelloy C-276 require controlled heat treatment to achieve optimal properties.

- In electronics manufacturing, Kovar alloys require precision sealing technology.

Choosing alloys that are easier to machine can reduce production time and costs.