Carbon Steel

As a professional carbon steel supplier, HuaRun Metals provides a full range of carbon steel materials, including hot-rolled and cold-rolled sheets, structural plates, seamless pipes, welded tubes, and round bars.

We supply popular grades such as 1018, 1040, 1045, 1060. 1075, 1080, 1095, and others. With a stable supply chain, factory pricing, and global export experience, we help customers source the right carbon steel products quickly and reliably.

Contact our team today for competitive carbon steel prices!

Carbon Steel Grades

Low Carbon Steel: A36, 1010, 1020, etc.

Medium Carbon Steel: 1045, 1035, etc.

High Carbon Steel: 1080, 1095, etc.

Carbon Structural Steel: A283 Gr.C, A572 Gr.50, etc.

Carbon Steel Pipes: ASTM A106 Gr.B, ASTM A53, API 5L Gr.B, et.

High Strength Low Alloy Steel: A572 Gr.50, A588, etc.

Carbon Steel Forms

- Sheets/Plates: No.1, 2B, 2D, Perforated, Checker, etc.

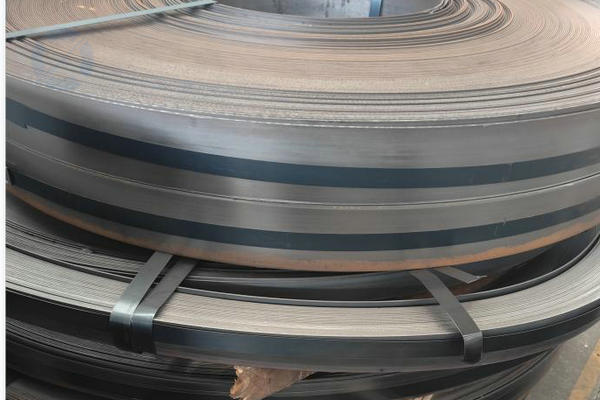

- Coils/Strips:

- Bars: Round, Square, Flat, Hexagon, rectangular, etc.

- Tube: Round, Square, Flat, Hexagon, rectangular, etc.

- Seamless Tube: Mechanical & Hydraulic, etc.

- Wires: Wire Rod, Wire Mesh, etc.

Carbon Steel Types

| Type | Carbon Content | Key Features | Applications |

|---|---|---|---|

| Low Carbon Steel | < 0.25% | High ductility, good weldability, low cost | Automotive panels, pipes, construction |

| Medium Carbon Steel | 0.25–0.60% | Higher strength, better wear resistance | Machinery parts, axles, shafts |

| High Carbon Steel | > 0.60% | Very high hardness, less ductile | Cutting tools, springs, wear-resistant parts |

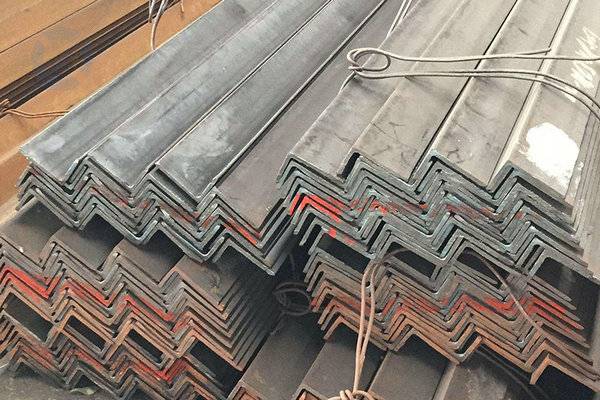

Carbon Steel Shapes

We provide carbon steel plates, coils, strips, bars, tubes, wires, etc. in different grades and specifications.

Ready to source high-quality carbon steel products?

HuaRun Metals is your trusted factory-based supplier, offering competitive prices and reliable delivery.

Get in touch with us to find the best carbon steel solution for your project needs!

Carbon Steel Applications

Construction and Architecture

Automotive and Transportation

Chemical and Petrochemical Industries

Energy and Power

How to Choose the Right Carbon Steel Grade?

Choosing the right stainless steel grade is essential to ensure performance, durability, and cost-effectiveness for your project. At HuaRun Metals, we help customers worldwide select the most suitable material based on their application, environment, and budget. Here are some professional recommendations:

Understand Your Application Environment

The use environment determines the temperature, humidity, corrosion level, load, and other conditions that carbon steel faces during use. Choosing the right carbon steel material can ensure its durability and reliability in a specific environment.

Wet or Corrosive Environment:

Recommended materials: AISI 4130, AISI 4140 (alloy steel), AISI 1045 (medium carbon steel)

Reason: These steels contain alloying elements (such as chromium, molybdenum, etc.), which can provide better corrosion resistance in wet or corrosive environments. Alloy steel has stronger corrosion resistance than ordinary carbon steel and is suitable for mechanical equipment and automotive parts.

High-Temperature Environment:

Recommended materials: AISI 1045, AISI 4130, AISI 8620 (alloy steel)

Reason: In high-temperature environments, alloy steels are generally better in strength and wear resistance than ordinary carbon steels. They can maintain good mechanical properties at higher temperatures and are suitable for mechanical parts in high-temperature working environments.

Low-Temperature Environment:

Recommended materials: AISI 1018 (low carbon steel), AISI 1045 (medium carbon steel)

Reason: Low-carbon steel usually has better toughness and can prevent brittle fracture in low-temperature environments. For low-temperature working conditions, low-carbon steel and some medium-carbon steel are better choices.

Know the Required Mechanical Properties

Mechanical properties (such as strength, hardness, toughness, wear resistance, etc.) are one of the most important factors when selecting carbon steel materials.

High Strength Requirements:

Recommended materials: AISI 1095 (high carbon steel), AISI 52100 (high carbon chromium steel)

Reason: High carbon steel has high strength and hardness, and is suitable for important parts that require high strength and wear resistance (such as tools, springs, gears, etc.). AISI 52100 steel is widely used in high-load parts such as rolling bearings and gears due to its high strength and wear resistance.

Wear Resistance Requirements:

Recommended materials: AISI 1060 (high carbon steel), AISI 52100 (high carbon chromium steel)

Reason: High carbon steel and alloy steel (such as 52100 steel) can provide excellent wear resistance after proper heat treatment. Suitable for working conditions that require wear resistance, such as tools, bearings, stamping dies, etc.

Toughness Requirements:

Recommended materials: AISI 1018 (low carbon steel), AISI 1045 (medium carbon steel)

Reason: Low carbon steel has high ductility and toughness, and is suitable for applications that require good toughness and impact resistance (such as structural parts, body parts, etc.). AISI 1045 steel provides a good balance between strength and toughness.

Fatigue Resistance Requirements:

Recommended materials: AISI 4130 (alloy steel), AISI 1045 (medium carbon steel)

Reason: Alloy steel (such as 4130 steel) can significantly improve fatigue resistance through the addition of alloying elements, and is suitable for high-strength, long-term load applications (such as aircraft parts, racing car frames, etc.).

Cost

Cost is an important factor that must be considered when selecting materials. Different types of carbon steel and alloy steel vary greatly in price. Generally, alloy steel and high-carbon steel are more expensive than ordinary low-carbon steel.

Low-Cost Demand:

Recommended material: AISI 1018 (low carbon steel)

Reason: Low-carbon steel is usually cheaper than medium-carbon steel and high-carbon steel. It has good weldability, machinability, and ductility, and is suitable for structural parts with low manufacturing costs and low load requirements.

Medium Cost Demand:

Recommended material: AISI 1045 (medium carbon steel), AISI 4130 (alloy steel)

Reason: Medium carbon steel has good strength and machinability, and is suitable for medium-strength mechanical parts. Although alloy steel is more expensive, it has advantages in high strength and corrosion resistance and is suitable for medium-sized mechanical equipment that requires certain performance.

High-Cost Requirements:

Recommended materials: AISI 52100 (high carbon chrome steel), AISI 1095 (high carbon steel)

Reason: High-carbon steel and high-carbon chrome steel (such as 52100 steel) have very high strength and wear resistance and are suitable for demanding high-load, high-speed working environments. However, they are more expensive and are suitable for important, high-value industrial parts.

Machinability

Machinability refers to the processing properties of a material such as cutting, welding, and forming. Different carbon steels have different processing properties due to their different compositions.

Easy to Process and Weld:

Recommended material: AISI 1018 (low carbon steel)

Reason: Low carbon steel has good machinability and weldability, is suitable for applications with high processing requirements, and can be easily welded to form complex shapes.

Moderate Machinability:

Recommended material: AISI 1045 (medium carbon steel), AISI 4130 (alloy steel)

Reason: Medium carbon steel and alloy steel generally have good mechanical properties, but may increase the processing difficulty slightly during processing. AISI 1045 steel is suitable for general processing, while AISI 4130 steel requires more sophisticated processing to ensure its performance.

Difficult to Process and Weld:

Recommended material: AISI 1095 (high carbon steel)

Reason: High-carbon steel is usually hard and difficult to process and weld. It is suitable for processing parts into simpler shapes, but not suitable for complex processing requirements.