Aluminum Alloy

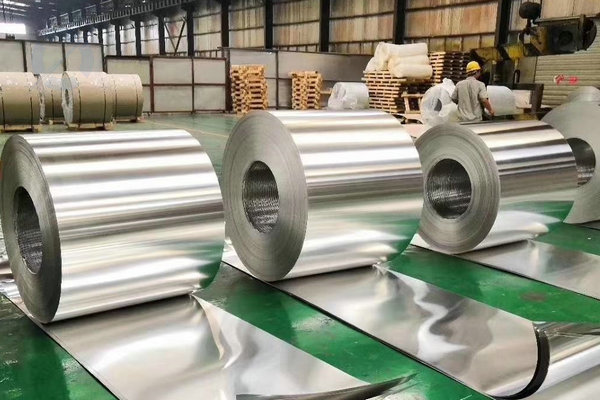

HuaRun Metals is a leading aluminum material supplier in China, offering a wide range of aluminum products such as plates, sheets, coils, strips, pipes, wire, and bars.

We provide various alloy grades including 1050, 1100, 2024, 3003, 5052, 6061, 6063, and 7075, serving industries like transportation, construction, packaging, and aerospace. All materials are processed to meet your technical requirements with mill test certificates.

Quick delivery and custom sizes available – send us your aluminum inquiry today!

Aluminum Alloy Grade

1000 Series Aluminum Alloy: 1050, 1060, etc.

2000 Series Aluminum Alloy: 2011, 2014, 2024, etc.

3000 Series Aluminum Alloy: 3003, 3004, 3005, etc.

5000 Series Aluminum Alloy: 5052, 5083, etc.

6000 Series Aluminum Alloy: 6061, 6082 etc.

7000 Series Aluminum Alloy: 7075, 7050, etc.

- 8000 Series Aluminum Alloy: 8011, etc.

Aluminum Alloy Forms

- Sheets/Plates: No.1, 2B, 2D, Perforated, Checker, Embossed, Etch, Mirror, BA, No.4, etc.

- Coils/Strips:

- Bars: Round, Square, Flat, Hexagon, rectangular, etc.

- Tube: Round, Square, Flat, Hexagon, rectangular, etc.

- Seamless Tube: Mechanical & Hydraulic, etc.

- Wires: Wire Rod, Wire Mesh, etc.

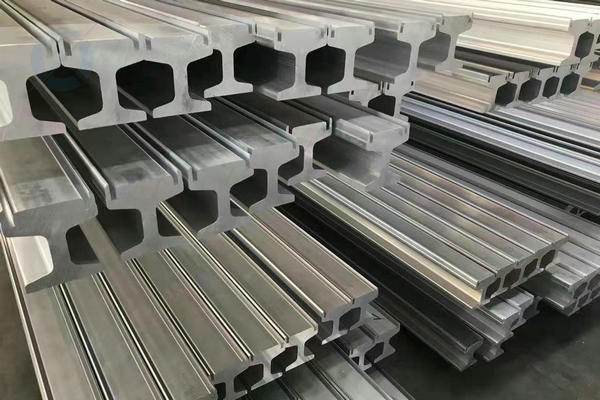

Aluminum Shapes

We provide aluminum alloy plates, coils, foil, foam, strips, bars, tubes, wires, aluminum profiles, etc. in different grades and specifications.

Ready to source high-quality aluminum alloy products?

HuaRun Metals is your trusted factory-based supplier, offering competitive prices and reliable delivery.

Contact us today for a free quote and customized solution for your project needs!

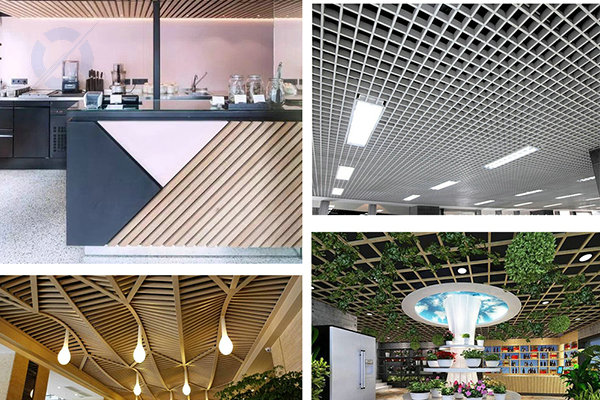

Aluminum Alloy Applications

Construction and Building Facades

Automotive Parts and Components

Aerospace and Aviation Structures

Marine and Shipbuilding Industries

Energy and Electrical Systems

How to Choose the Right Aluminum Alloy?

Selecting the right aluminum alloy is critical to ensuring a successful project. Huarun Metals offers a wide variety of aluminum alloys to meet the needs of a wide range of industries. Understanding the key factors in alloy selection can help you make the best decision regarding performance, cost, and durability.

Identify Your Application Requirements

First, identify the purpose and application of the aluminum:

Structural strength – do you need a high-strength material to withstand heavy loads?

Corrosion resistance – will the material be exposed to moisture or chemicals?

Formability – will the material be bent, shaped, or punched?

Weldability – is welding performance a key factor?

Surface finish – do you need an aesthetic appearance or a special coating?

Weight – is lightweight performance a priority for you, such as in the automotive or aerospace fields?

Please feel free to contact us to find the right aluminum alloy for your project!

Understand the Major Aluminum Alloy Series

| Alloy Series | Key Characteristics | Typical Applications |

|---|---|---|

| 1000 Series | Pure aluminum, excellent corrosion resistance, high conductivity | Electrical, chemical equipment |

| 2000 Series | High strength, excellent machinability, lower corrosion resistance | Aerospace, automotive structural parts |

| 3000 Series | Good formability and corrosion resistance | Roofing, siding, cooking utensils |

| 5000 Series | High strength and corrosion resistance, excellent weldability | Marine, transportation |

| 6000 Series | Good strength, corrosion resistance, excellent extrudability | Structural components, automotive frames |

| 7000 Series | Very high strength, heat-treatable, lower corrosion resistance | Aerospace, sports equipment |

Match the Alloy to Your Processing Needs

Different aluminum alloys respond differently to fabrication processes:

5052 – Excellent for bending and welding, ideal for marine use.

6061 – Versatile and strong, good for machining and structural applications.

7075 – Extremely strong, used in aerospace but more difficult to weld.

If your project involves cutting, machining, welding, or coating, we recommend discussing the processing options with our engineers for optimal performance.

Consider the Cost-Performance Balance

While high-strength alloys such as 7075 offer excellent performance, they come at a higher cost. For many structural or general applications, 5000 and 6000 series alloys offer the best balance between cost and performance.

Contact us today for a material recommendation that fits your project budget without sacrificing quality.